Water storage and supply was identified as a critical component for the long-term security, sustainability and growth of the Mount Buller resort in summer and winter. CMP completed the functional and detailed design of the Mount Buller Water Storage facility. The facility will be used to provide water security for the township, improve firefighting capability and increase the resorts snow making capacity. The upgrade included:

Water storage and supply was identified as a critical component for the long-term security, sustainability and growth of the Mount Buller resort in summer and winter. CMP completed the functional and detailed design of the Mount Buller Water Storage facility. The facility will be used to provide water security for the township, improve firefighting capability and increase the resorts snow making capacity. The upgrade included:

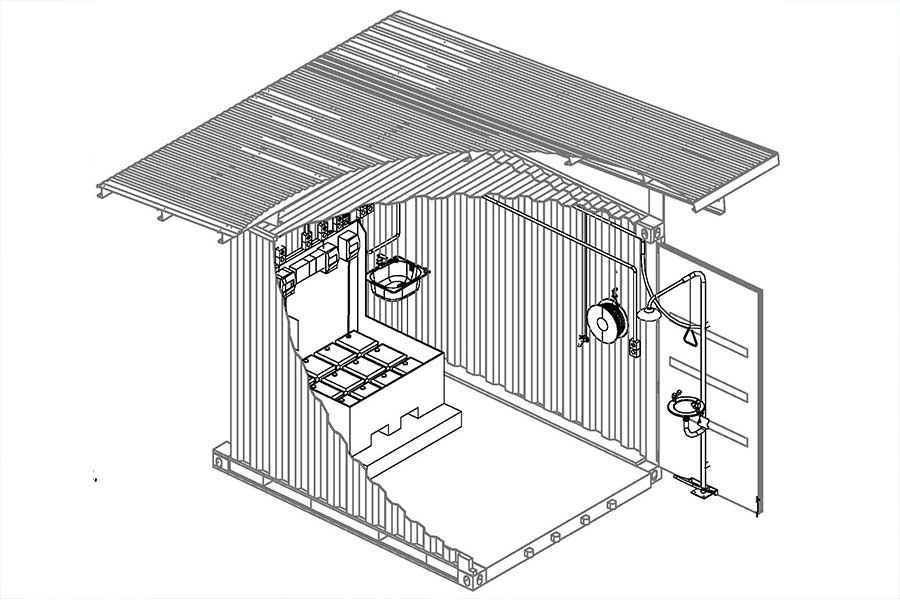

CMP prepared a detailed design for the hypochlorite dosing facilities for installation in remote indigenous communities in the Northern Territory.

The design had to allow for pre-fabrication and transport to site as well as potential weather conditions once installed, including cyclones.

The dosing units were based on the equipment installation inside a standard 10ft shipping container with an awning being installed once on site. Chemical storage was in multiple 20 L containers which could be switched out as they were emptied.

The trunk sewer ventilation systems at North Weston and Crace were in need of upgrade to minimize the risk of odour issues for nearby residents, meet performance criteria for sewer ventilation, and to prevent corrosion.

CMP was engaged to undertake the detailed mechanical, electrical, civil and structural design of a new trunk sewer ventilation systems at the two sites as outlined below.

North Weston: Scope included:

Crace: Scope included:

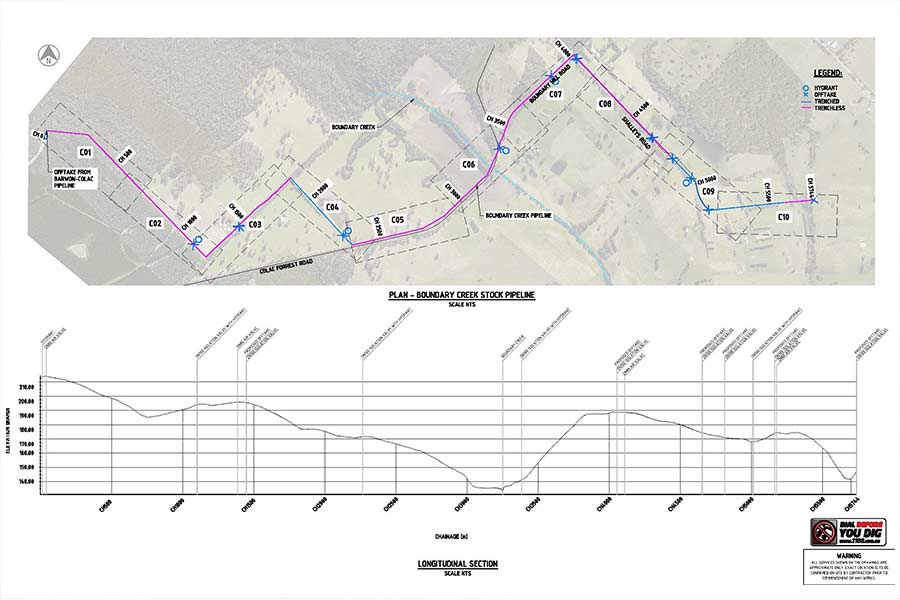

Boundary Creek Stock Pipeline is a key project for Barwon Water, facilitating the supply of raw water to a number of landowners in the Yeodene region to supplement flows taken from Boundary Creek.

The project involved the concept and detailed design of 7 km of PE pipeline. This included a pressure reducing station at an offtake to the existing Barwon-Colac Raw Water Supply pipeline that could cope with large pressure variations, as well as flow control devices at each of the landowner connection points. CMP worked with Barwon Water’s project managers, survey team, environmental team, and a number of key stakeholders to deliver this project on time and within budget.

CMP was engaged to undertake the detailed mechanical, civil and structural design for the upgrade of the TasWater’s Blackmans Bay Sewage Treatment Plant as part of the Kingborough Sewerage Project. The upgrade included:

The Pakenham STP upgrade for South East Water included the following works:

Due to mixing complexities and the particularly aggressive/difficult nature of the incoming sewage, specialised investigation and testing was undertaken including:

The additional design effort put in “up front” worked well, as South East Water was able to ensure project requirements were well documented and the system was easy and straight forward to initially commission.

Cost Savings: All significant upgrade components were analysed in detail over a range of options to determine the most appropriate option. The tank height and depth were optimised for capital and operational expenditure. The cost savings to South East Water were in excess of $1.5M.

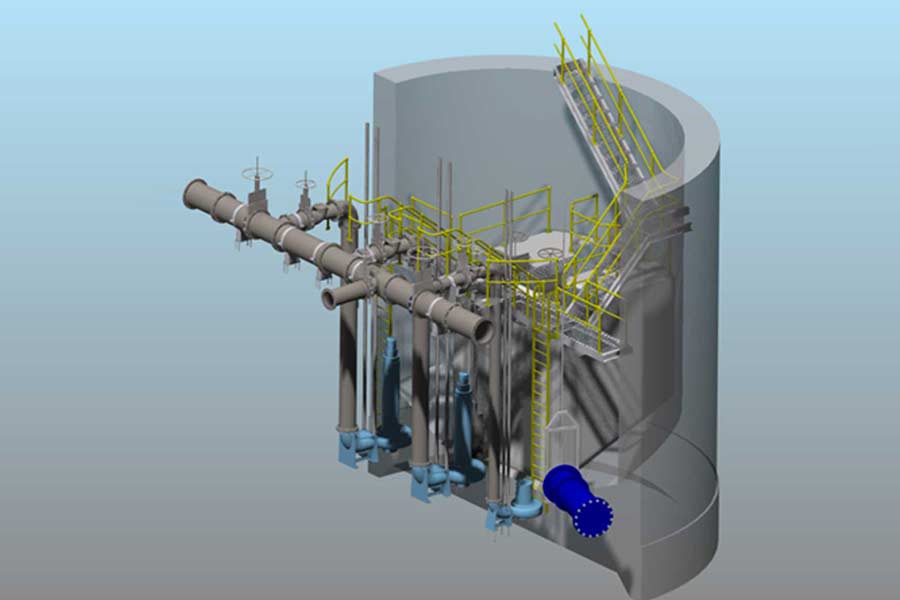

Through the design and construct team Aqua Metro Services, we undertook the upgrade of the Sugarloaf Reservoir Pump Station (RPS) service water system. The RPS service water system supports the three 1.6MW main pumps which maintains throughput to the Winneke Water Treatment Plant. The project scope entailed optioneering replacement equipment with Melbourne Water stakeholders and incorporated modern design technology to minimise clashes with existing services, as well as allow for construction to be undertaken with the facility available at short notice.

Key project highlights include the following:

Challenges with construction resulted in a staged approach being performed, with MWC stakeholders heavily involved in the outage planning with AMS Design and Construction team members.

As part of the design and construct team Aqua Metro Services, we completed the detailed design and construction of water, sewerage, power, communications, and firefighting services to support Melbourne Water’s extensive restoration of the historic Cocoroc Precinct with the Western Treatment Plant.

These 144 kL steel fire water tanks and diesel pumpset are connected to more than 800m of fire supply ring main, providing protection to a new administration building, workshop, and education facility.

Melbourne Water made the decision to relocate the Western Treatment Plant administration office complex on New Farm Road in Werribee away from rapidly encroaching residential developments in order to locate operators and service providers closer to the plant. The new office complex at the WTP Cocoroc Precinct provides accommodation for WTP operations and maintenance staff and for community education programs. The new administration and maintenance shed buildings were occupied in August 2019.

The purpose of this project was upgrade access roads and security at the WTP Cocoroc Precinct to comply with MWC’s security and safety standards.

Key project design features included the following:

As part of the design and construct team Aqua Metro Services, we completed the design and construction of an effluent monitoring station at Melbourne Water’s Eastern Treatment Plant. The project involved the construction of a shelter and a sample tank, and the fitout pumps, piping and instrumentation. The instrumentation supplied for monitoring was COD, total suspended solids, pH, temperature and ammonia.

Through the design and construct team Aqua Metro Services, we completed the design and installation of an evaporative cooling system for Melbourne Water’s Eastern Treatment Plant power station. The evaporative system was to augment existing ventilation as well as provide cooling capacity.

Over 30% of ETP’s power requirements are generated from the cogeneration power station. The heat load within the power station building is excessive for operations and maintenance personnel, with temperatures regularly in excess of 50 oC.

The existing system consisted of filtered ventilation fans only, with no cooling capacity. External air was distributed through three levels of the power station building by fans located in the in the building’s basement. Previous remedial ventilation works had not been successful at reducing the engine room temperatures to satisfactory levels.

The installation of a supplementary evaporative cooling system was identified as the preferred solution in MWs options assessment.

As part of detailed design, a 3D CAD model was developed from existing drawings and a drone photo survey. The model was used to improve tie in of the new equipment into existing spaces and was critical during the safety in design and constructability reviews. It enabled improved consideration of maintenance access and potential equipment and construction clashes.

As part of the design and construct team Aqua Metro Services, we completed the design and construction for the new carpark facilities at Eastern Treatment Plant. This project involved the conversion of an existing temporary gravel carpark into a fully sealed permanent facility.

As part of the design and construct team Aqua Metro Services, we completed the detailed design, technical site supervision and as-constructed drawings for Melbourne Water Corporation’s bulk water meter upgrade program. The flow meters vary in size from DN800 to DN1600 and have been cut into steel pipelines of up to DN2000. The works included replacement of pipe upstream and downstream of the flow meters to ensure internal diameters matched the bore of the meter for greater reading accuracy.

Yering Gorge pump station transfers water to Sugarloaf Reservoir from the Maroondah Aqueduct and the Yarra River. The facility has been in operation for approximately 40 years as part of the larger Winneke Water Treatment Plant.

Through the design and construct team Aqua Metro Services, we completed the design for the replacement of the two service water strainer sand the by-pass pressure regulating valve assembly under a design and construct project. The former Gordon Marr & Sons strainers were removed and replaced with Amiad ABF-10k series units. The by-pass regulating valve assembly was redesigned to address historical problems with blockages due to organic material from the two available raw water supplier.

CMP completed concept, functional and detailed design of the Pakenham Main SPS and Inlet Works upgrade to take the capacity from approximately 130 L/s to 415 L/s using the existing site.

This required a significant amount of detailed hydraulic analysis to determine the optimum screen velocities and determine how the capacity of the existing system could be significantly increased without the need to duplicate building footprints.